Warning Line System Osha

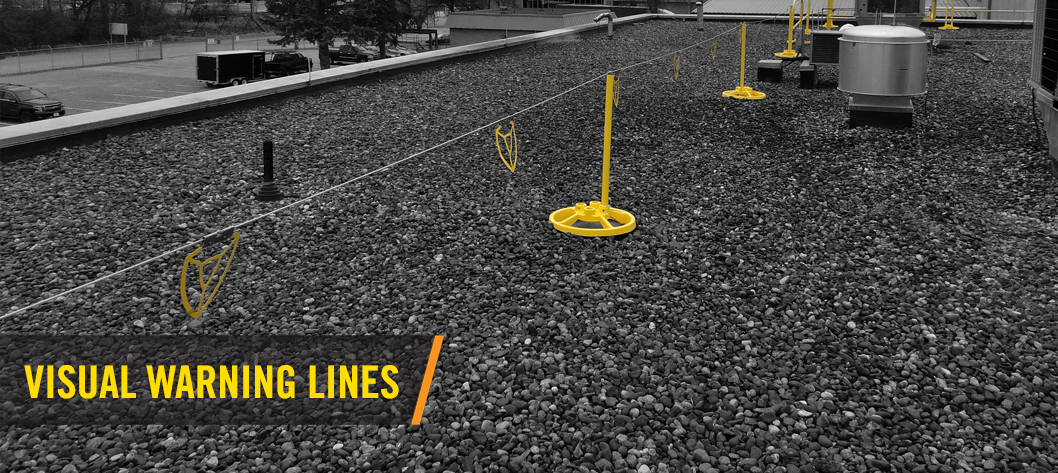

Warning line system osha. A warning line is a barrier such as rope wire or chain that warns workers they are approaching an unprotected edge of a roof floor or other work surface. No work or work-related activity will take place between the edge and the warning line. The work area must be surrounded by the warning line and must be at least six feet from all sides.

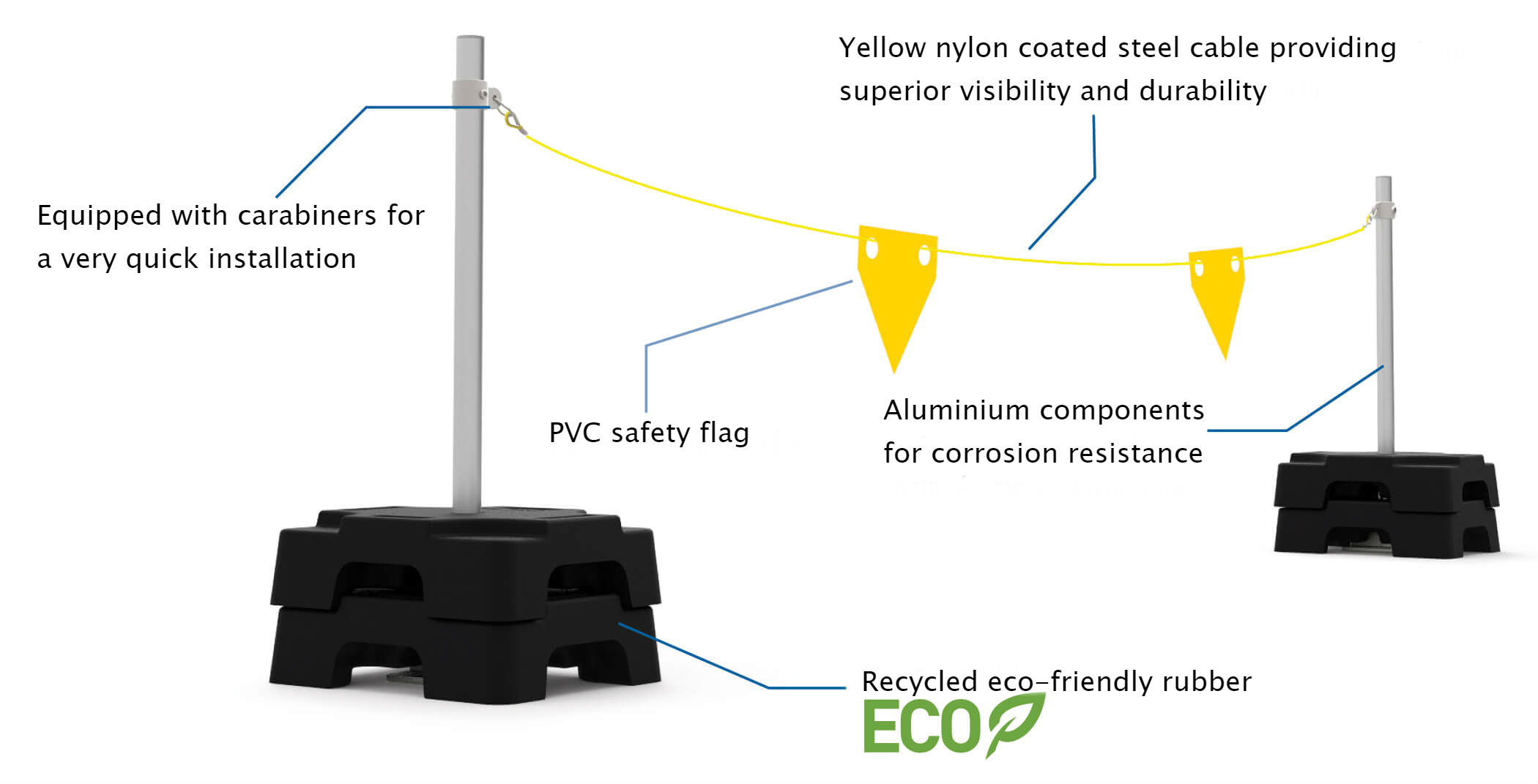

Although according to 29 CFR 191028 b 13 ii on low-slope roofs when work is done between 6 and 15 ft from the edge and is either temporary or infrequent a designated area using warning lines may be used The warning line meets or exceeds the OSHA warning line requirements. All warning lines must be flagged with a highly visible material and spacing must not exceed 6 feet intervals. Meets OSHA Regulations 16 lb pull test.

No work or work-related activity is to take place in the area between the warning line and the edge. The warning line meets or exceeds the requirements in 1926502f2. It should be erected no less than 6 feet from the roof edge.

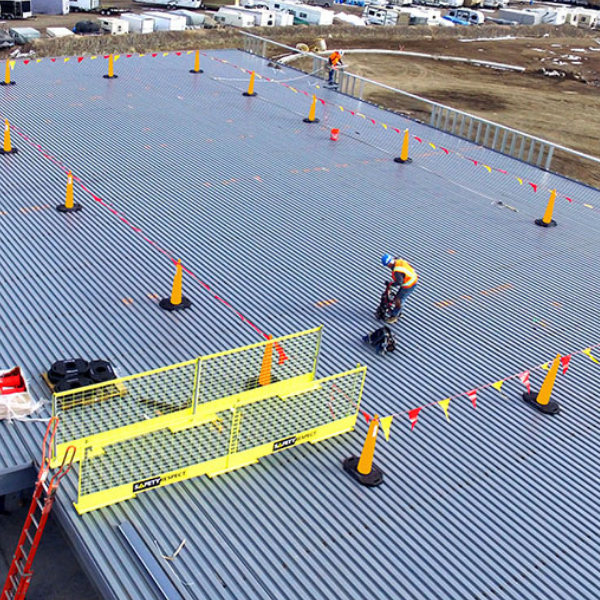

Plastic cones are stackable for easy transportation and storage. Warning line systems and their use must comply with the following provisions. With access to any roof safety and OSHA compliance should be top of mind.

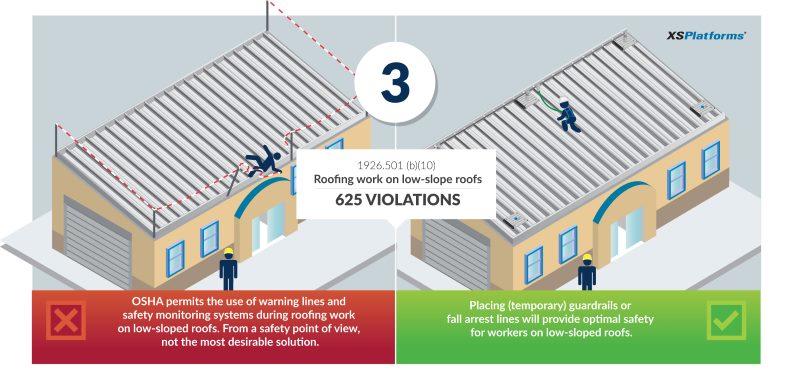

The following safety huddle lists the OSHA standards that regulate and define the specifications for warning line systems in construction fall protection. Product and warning line systems. The warning line system can be used to provide fall protection on roofs with slopes of 412 or less.

The victim was not using any type of fall protection devices or systems. OSHAs mission is to assure safe and healthful working conditions for working men and women by setting and enforcing standards and by providing training outreach education and assistance. Warning line can be an integral part of your fall protection plan.

A Warning Line System provides a visual fall protection warning Although your work area may be deemed OSHA compliant with fall protection warning lines in place it is important to remember that these systems do NOT physically restrain workers from traveling into dangerous areas nor do they arrest falls. OSHA will consider use of a warning-line system alone only a de minimis violation of the standard if the following are met.

OSHA has had some recent interpretations on warning line systems.

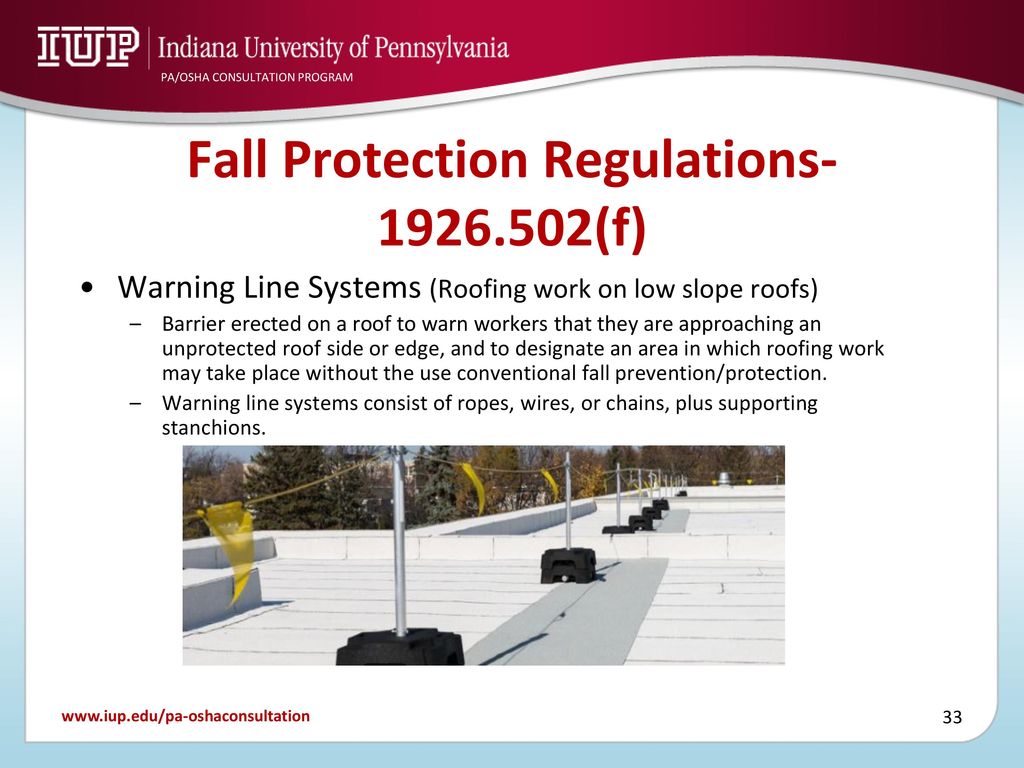

It should be erected no less than 6 feet from the roof edge. Learn more about how to. OSHA has had some recent interpretations on warning line systems. Warning Line OSHA Fall Protection Training Roofing Work Workplace Accidents - YouTube. The warning line meets or exceeds OSHAs setup requirements. Warning lines are to be supported so the lowest point of the sag is no less than 34 inches and no more than 39 inches from the walkingworking surface. The warning line system shall be installed used and removed under the supervision of a competent person. A warning line is used 15 feet or more from the edge. The following safety huddle lists the OSHA standards that regulate and define the specifications for warning line systems in construction fall protection.

Warning Line Systems The Occupational Safety and Health Administration OSHA is an agency of the United States Department of Labor. What is a Warning Line. Plastic cones are stackable for easy transportation and storage. Which are supported by stanchions that are designed to withstand being tipped by 16 pounds of pressure 30 from the walking or working surface. The warning line meets or exceeds the requirements in 1926502f2. A combination of conventional fall protection systems and warning line systems or A warning line system and a safety monitoring system. The following safety huddle lists the OSHA standards that regulate and define the specifications for warning line systems in construction fall protection.

Post a Comment for "Warning Line System Osha"